SurfaceTreat

PLASMA – green technology of surface treatment

LA 400 - Low pressure laboratory equipment

Equipment is used to generate plasma in vacuum. Plasma is generated by means of microwave source.

Standard equipment content:

- chamber volume 64 l

- 3-4 MFC 100/200 sccm

- mixing system for powder or granulates with variable rates 6 – 212 min-1, volume 2,5 l (typical example 250 – 350 g of PE powder with 350 µm particle size)

- roll – to – roll system for foil or textile treatment (rewinding speed 0 – 20 mm/min); maximum width of the cloth roller 130 mm, recommended width up to 105 mm. Length depends on the textile thickness, maximum package diameter is 215 mm at minimum diameter of inner roller 25 mm (typical example – nonwoven fabric with thickness 3 mm – package length 10 m)

- rotating disc – diameter 200 mm for homogenous treatment of plastic products with variable rates 6 – 212 min-1

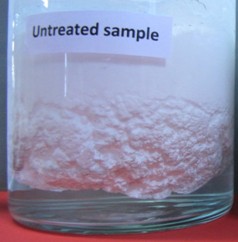

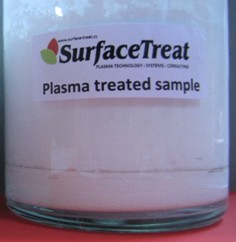

- touch display control in manual mode

Application example – powder hydrophilisation – additives for paints – waxes, textures – significant improvement of dispersion ability, agglomeration elimination; powders for rotomolding – effect stays also after sintering – enhancement of wettability and adhesion surface properties – application prior to PUR foaming, gluing, printing; particle size of processed materials from 8-800 micrometers

PE powder dispersion before treatment

PE powder dispersion after treatment

Application example – surface pretreatment (hydrophilisation/adhesion enhancement) of plastic parts prior to final processing – surface activation prior to printing, adhesive bonding, painting; surface cleaning, etc.

PEEK surface energy before treatment (< 36 mN/m)

PEEK surface energy after plasma treatment (> 44 mN/m)

- Equipment is suitable for testing and development batch processes and can be used in research institutes, universities, small productions or laboratories.

- Application in in the area of automotive, machine engineering, chemical industry, for medical purposes, etc.

Proudly created by Meatballs, s.r.o., 2017