SurfaceTreat

PLASMA – green technology of surface treatment

Surface energy measurement – inks and pens by Arcotest GmbH

The surface energy is one decisive criterion for the adhesion of printing ink, glue, varnish, etc. on many plastic and metal surfaces. It is given in mN/m. Apart from some exceptions the general rule is: The higher the surface energy of a material the better the adhesion of anything meant to be fixed to its surface. As a general limit 38 mN/m is often mentioned for good adhesion on the surface.

Test inks and test pens by ARCOTEST GmbH are used for the determination of the surface energy value. This serves well to find out about the quality of a treatment process. This testing method is suitable for the operating personnel on any production line as a routine check, when the result can be immediately evaluated and gives a very clear picture of the degree of treatment. The accuracy of the measurement is ±1 mN/m.

Practical example of surface energy measurement using inks you can see on video sequence Surface energy of sintered surfaces.

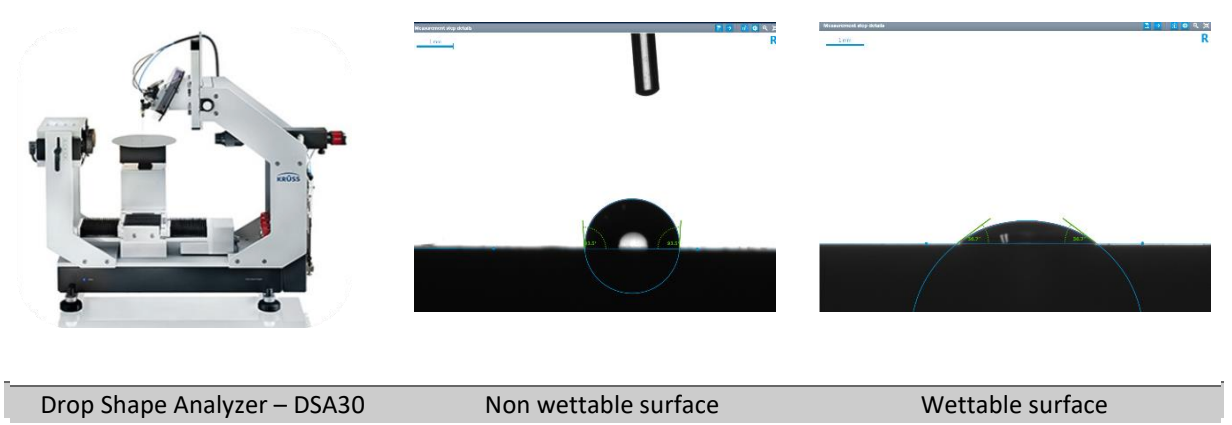

Contact angle measurement by Drop Shape Analyzer

This method is used for special analyzes of surface quality after plasma treatment compared to untreated sample or for quality testing of the initial material (untreated). The measurement is used also as the surface quality testing of initial material before processing or between different production cycles to observe critical moments in the case of problems with gluing, printing or any further processing.

Measurement of contact angle is done using Drop Shape Analyzer – DSA30. The contact angle is given by the angle between the sessile drop and the sample surface. The contact angle between 0° and 90° is wettable, above 90° it is not wettable. So, when contact angle decreases the wettability improves. The measurement of contact angle is characterized for solid samples. The measured values are compared to the untreated sample. Usually, 10 drops are measured for each sample and deviations are determined. We provide the technical protocol with analyzed results on request. The special SW is available to calculate the surface energy of the substrate using different mathematical models. In this case 2 different liquids are used and then the surface energy is calculated.

Please, contact us for further details.

Material PTFE

Contact angle before modification 150°

Material PTFE

Contact angle after modification 20°

Material: PBT

Contact angle before modification 85°

Material: PBT

Contact angle after modification 40°

Material: TPU

Contact angle before modification 92°

Materiál: TPU

Contact angle after modification 40°

Proudly created by Meatballs, s.r.o., 2017